Introduction

A grand challenge facing our planet is the problem of mismanaged plastic waste that finds its way into the environment (“environmental plastic waste”). This problem is especially acute in developing countries or other infrastructure-limited regions. Collecting and converting environmental plastic waste to liquid fuel that can replace other conventional fossil or biomass fuels is, so far, the only technology that permanently removes plastic from the environment and leads to a net reduction in greenhouse gas emissions, on a life cycle basis.

Converting environmental plastic waste into fuel oil makes particularly good sense where the converted environmental plastic waste has already escaped collection for potential recycling, has become dirty and heterogenous, and thus will not be used as a feedstock for secondary plastic production. It also makes the most sense where the produced polyfuel replaces conventional fossil fuel.

To appreciate this solution, the problem must first be recognized. Most environmental plastic waste cleanup efforts fail where there is no beneficial use identified for the collected environmental plastic waste. Again, this environmental plastic waste, once collected, is not suitable for recycling, and therefore will find its way back to the environment unless it is destroyed. Currently, there is no incentive for community members in developing countries to collect environmental plastic waste at all. This proposed project resolves both problems by achieving a beneficial use for the environmental plastic waste, with a lower greenhouse gas (GHG) lifecycle footprint, while providing incentives for community support and implementation.

Background

1. The Global Plastic Waste Crisis

Currently, plastic can be found at the top of the world (Napper et al., 2020), the bottom of the world (Chiba et al., 2018), and in the placentas of mothers (Ragusa et al., 2021), so life will never experience a world without plastic. Plastic production and subsequent waste generation has skyrocketed in the past couple of decades and continues to increase (Geyer et al., 2017). It’s estimated that more than 8.3 billion metric tons of plastic has been produced since its inception just over a century ago. 79% of all this plastic is calculated as going into landfills or the natural environment (Geyer et al., 2017). 9% of the 8.3 billion MT is thought to have been recycled, but most recyclable content is only structurally sound enough to be recycled fewer than a dozen times before it too must be landfilled or disposed of. Recycling systems are heavily flawed for many reasons. Whether it be because of limitations with traditional mechanical recycling methods, too little governmental (financial) support, or corporations making it too difficult for the consumer to recycle (mixed plastic/material packaging). This leads to consumer confusion on what to purchase and how to dispose of those purchases on local and global levels (Bennett and Alexandridis, 2021).

In 2016, the U.S. generated more plastic waste than any other country, exceeding that of all European Union member states combined (Law et al., 2020). This is a luxurious and wasteful lifestyle that many around the world are starting to emulate, leading to the trend of globally producing much more waste annually. It is important to emphasize that current per capita waste generation in developed countries is much higher than in developing countries (Liu et al., 2018). Much of the municipal solid waste (MSW), including plastic waste, which developed countries produce is either landfilled or shipped to the Global South. These countries tend to lack the waste management infrastructure that is needed to collect, sort, and treat their own MSW, and they certainly do not have the ability to properly deal with the influx of other nations' waste.

2. The Public Health Crisis from Solid Fuel Cooking

In developing countries, women hover over cookstoves for several hours a day. Burning fuels can release a combination of particulate matter, carbon monoxide, and sulfur dioxide, as well as other pollutants. Constant exposure to fuel emissions leads to eye and lung related illnesses. Approximately 7 million deaths annually are linked to air pollution, of which 4 million are due to household air pollution (Clean Cooking Alliance, 2021, WHO, 2021a). Indoor air pollution also increases the chance of early pulmonary and cardiovascular damage, particularly for longer and more intense exposures (Pratali et al., 2019). Burning biomass fuel (including wood, dung, and charcoal) increases the chance of respiratory infections, including pneumonia, tuberculosis, and chronic obstructive pulmonary disease (Fullerton et al., 2008). Sulfur dioxide emissions in particular have been associated with cardiovascular and respiratory mortality (Wang et al., 2018; Cao et al., 2022; Orellano et al., 2021; Hedley et al., 2002). Women are more directly exposed to air pollution because of cultural norms in many countries where women are responsible for most household cooking. Once exposed, women have a higher chance of contracting lung cancer, chronic obstructive pulmonary disease, and cardiovascular diseases (Ali et al., 2021). Not only does household air pollution have an effect on adults, but it also has an effect on infants and children. There is a relationship between solid fuel smoke exposure and low birth weight and stillbirths (WHO, 2021b). Indoor air pollution from solid fuel usage has also been found to be a factor for childhood pneumonia (WHO, 2021c). Children exposed to air pollution also have a higher chance of acute lower respiratory tract infections, anemia, and premature mortality (Ali et al., 2021). Indoor air pollution is an international issue that people must find equitable solutions for. The World Health Organization found that every year, 3.8 million people die from indoor air pollution tied to solid fuels and kerosene, 45% of pneumonia caused deaths in children under five are related to household air pollution, and 28% of pneumonia caused deaths for adults (WHO, 2021d).

3. Appropriate Technology

The concept of appropriate technology (AT) was first espoused by E.F. Shumaker (1973) in his book Small is Beautiful. It refers to “technological choices and applications that are small scale, decentralized, labor-intensive, energy efficient, environmentally sound, and locally controlled” (Hazeltine, 1999). AT is technology specifically designed for the community or individuals who will utilize it. In developing regions, appropriate technology means technology that is simple, low cost, easy to construct, safe, and easy to operate. This often means making tradeoffs, such as manual operation for sophisticated automatic control, used or repurposed parts for new ones, or hand-made for manufactured products. The purpose of AT is not to reproduce industrial technology on a small scale; instead, it is to design specific solutions based upon the resources available in a given region or for a given community (Seay et al., 2012). Converting polyolefin plastic waste to cooking fuel via slow pyrolysis can be easily accomplished using the principles of appropriate technology.

4. Converting Plastic Waste into Cooking Fuel

The chemistry to convert polyolefin plastic into liquid fuel is well established. Long chain plastic polymers can be broken down into shorter length chains that remain as a liquid at room temperature. The project team at Empowered Solutions for Environmental Sustainability has developed a low-cost, energy-efficient process for converting waste plastic into polyfuel using a simple to operate, small scale process. This technology has been successfully deployed in Uganda in collaboration with Makerere University. The typical method of waste plastic fuel production has relied on either fast-pyrolysis (thermal decomposition at elevated temperatures of 700- 900⁰C ) or utilizing a catalyst. This is problematic in rural regions, where reliable access to electricity, access to mechanical technological training and capacity is limited, and capital hinder the ability to implement pyrolysis technologies. Safety during operation is a further concern. Hence, slow-pyrolysis, utilizing simple, non-automated, low-cost technology operating at 300-450⁰C is preferred.

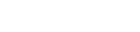

The Polyfuel Processor designed by Empowered Solutions for Environmental Sustainability utilizes the principles of AT. The process is a low-cost batch retort heated using an electric heating element. The thermal decomposition reaction is carried out in a retort, designed by the research team at Empowered Solutions for Environmental Sustainability. The retort is loaded with appropriate plastic, including high density polyethylene (HDPE), low density polyethylene (LDPE), and polypropylene (PP). The appropriate types of plastic are easily identifiable because the usable plastic will float in water. The process is turned on and the temperature is increased to approximately 350°C. After the initial heat up, the polyfuel processor can produce up to 1 liter of polyfuel/hour. One kg of waste plastic yields approximately 1 liter of fuel oil. This is a yield of 80% by mass, which is consistent with the available technical literature (Wong et al., 2015; Singh and Ruj, 2016). The Polyfuel Processor has been designed with ergonomics in mind to ensure that both women and men are able to lift and operate the process successfully. The Polyfuel Processor is shown in Figure 1 with a schematic in Figure 2. This process is low cost, simple, and safe to operate so it can be deployed in underdeveloped communities where plastic waste is most problematic. The process also poses a minimal risk to operators.

Of course, the process must be economically viable in order to be successful. The Polyfuel Processor illustrated in Figures 1 and 2 has a heating capacity to 3.0 kW. Using a typical electricity price of 0.20 USD/kWh and a price for waste plastic of 0.15 USD per kg, a 10 kg batch of mixed plastic will cost approximately 6.00 USD to convert to 10 liters of fuel oil. Using an average price for polyfuel of 1.20 USD/liter (based on current prices for traditional diesel fuel), the total value of the polyfuel produced will be 12.00 USD/batch, yielding a profit of 6.00 USD per day. Converting this mass of plastic into polyfuel will take up to 12 hours. A profit of 6.00 USD per day is significantly higher than the average daily wage, which is less than 2.00 USD per day in many developing countries. Factors which can potentially reduce this profit include higher energy costs, higher cost for sorted plastic waste, lower prevailing diesel fuel price and, perhaps most importantly, loss of efficiency due to poor insulation. The potential profit reported here represents a best case scenario.

Theory of Change

Environmental plastic waste causes harm to community members' personal health as well as their livelihoods, especially when the plastic waste is gathered into piles and burned in the open air. More than 90% of waste in low-income countries is burned in open-air piles (World Bank, 2018). The effect these open-air burn pits have on the environment largely goes unrecognized, as greenhouse gas emissions from burning trash are not counted in global inventories, further exacerbating climate change and the exaggerated impacts poorer community members are left to deal with in the future.

Environmental plastic waste is a major issue acutely impacting developing and infrastructure-limited regions. According to the Clean Cooking Alliance, in India alone over 789 million people - nearly 60 percent of the population - depend on polluting open fires or inefficient stoves to cook their food (Clean Cooking Alliance, 2019). These hazardous cooking techniques are mostly practiced not because of tradition or culture, but because it is the only way to survive, even though almost half a million Indians, mainly women, and children, die prematurely from practicing these cooking techniques. In addition to the impact on human life, the environment also suffers as 27-34% of wood harvested in 2009 was deemed unsustainable (Bailis et al., 2015). As a result, change is needed.

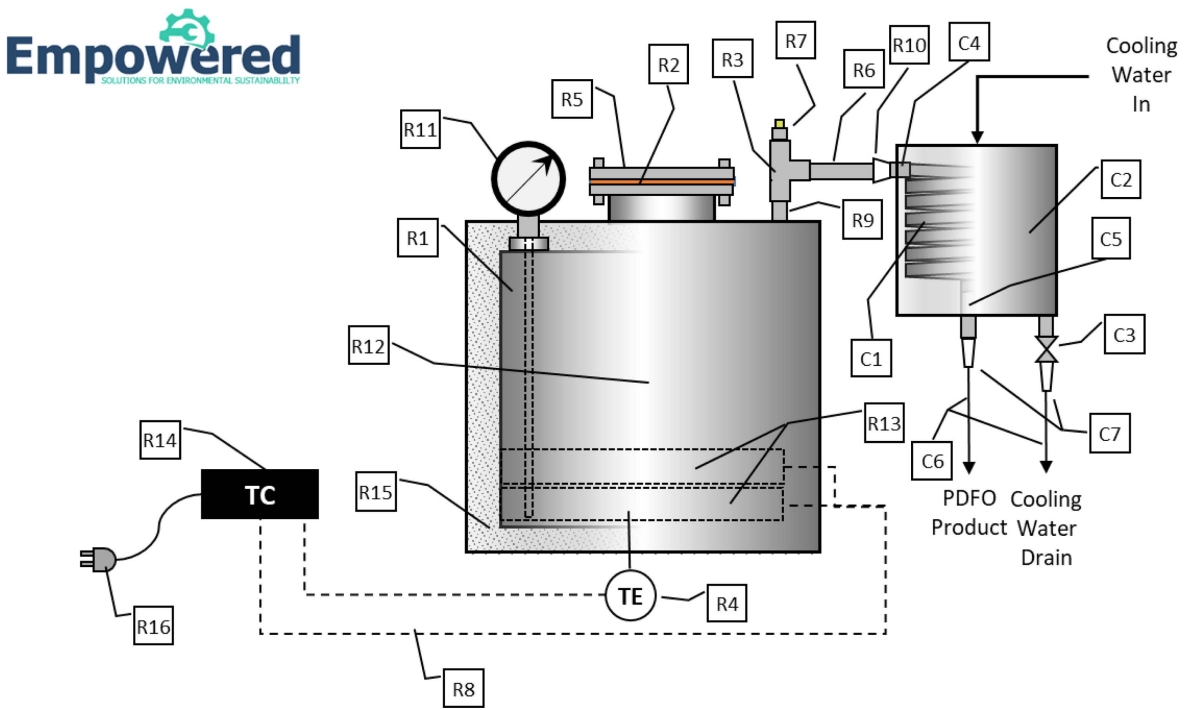

The theory of change for this process in Figure 3 aims to not only alleviate the negative impacts on community members, but simultaneously instill motivations for change and a sense of empowerment and pride of being a part of the global solution to be a part of a cleaner world. We assume that people care about their physical health, as well as that of their environmental surroundings. We also assume that people will make the switch to a cleaner cooking fuel to capitalize on the personal economic possibilities and start decentralized, circular economies within their communities.

Reduction in Indoor Air Pollution

1. Experimental Methods

Our hypothesis is that by switching from open fire cooking with solid fuels to cookstoves fueled with a liquid fuel oil produced from plastic waste, there will be a noticeable decrease in indoor air pollution. These pollutants include particulate matter, carbon monoxide, carbon dioxide, sulfur dioxide, and other trace chemicals.

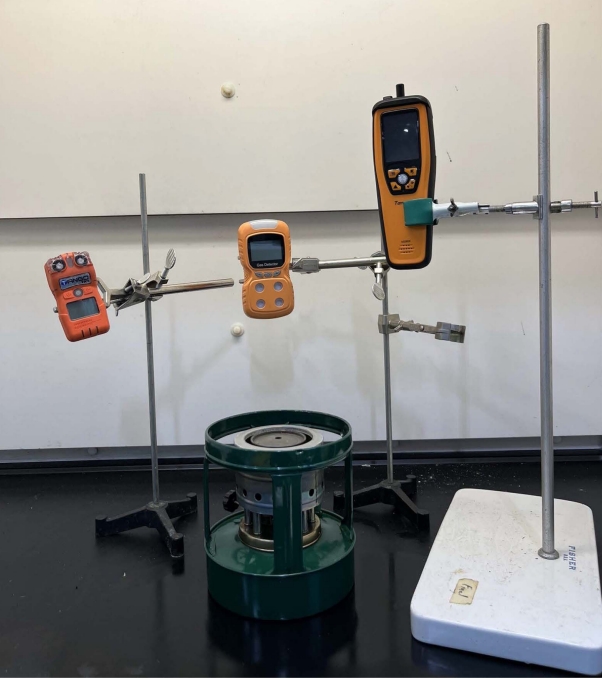

Particulate emissions (PM10 and PM2.5) and carbon dioxide were all measured using a Temtop M2000C Air Quality Monitor on three different cooking fuel options: Polyfuel, traditional kerosene fuel, and firewood. Carbon monoxide was measured using a multigas detector. Sulfur dioxide was measured using the Tango TX1 monitor. The liquid fuels were combusted in a standard 8-wick cookstove, as shown in Figure 4, which is common in developing countries. Emissions from fire wood were produced using an improved rocket stove, as illustrated in Figure 5.

During the experiment the stoves were placed in the center of the ventilation hood with the Temtop M2000C Air Quality monitor, multigas detector, and Tango TX1 monitor held by utility clamps placed on a ring stand as shown in Figure 6. The monitors were placed at the distance someone cooking would be, which was approximately one foot away. For all three of the cooking fuel options the cookstoves were lit on their highest setting. The stove burned until the readings of particulate emissions and carbon monoxide had stabilized. The readings tended to vary in the beginning due to the process of lighting the flame. Once the particulate emissions, carbon monoxide, and sulfur dioxide readings had stabilized, data was recorded every three minutes.

2. Results and Discussion

After collecting the data, the average PM2.5, PM10, particulates, carbon dioxide, carbon monoxide, and sulfur dioxide for wood, kerosene, and polyfuel were calculated, along with their standard deviations, as shown in Table 1.

The results indicated that polyfuel has substantially lower particulate matter emissions in comparison with fire wood, which produced a PM2.5 reading averaging 325.6 μg/m3. In comparison, polyfuel produced an average PM2.5 reading of 7.7 μg/m3. PM10 readings for firewood were also higher, averaging 480.7 μg/m3 compared with a reading of 11.2 μg/m3 for polyfuel. The large difference in the particulate matter emissions indicate that polyfuel is a cleaner alternative when compared with wood. As expected, particulate matter readings for kerosene were similar to readings for polyfuel. Kerosene produced an average PM2.5 reading of 6.9 μg/m3.

Conclusions

This research has shown that polyfuel is a viable option for cooking in developing countries. Particulate emissions are significantly lower than fire wood and sulfur dioxide emissions are significantly lower than kerosene. In conclusion, the dual crises of mismanaged plastic waste and indoor air pollution can begin to be addressed in developing regions through the application of AT designed processes. Converting plastic waste into sulfur-free cooking fuel can not only empower communities and individuals to take local control of their waste management challenges but also the public health challenges of indoor air pollution from cooking.

PDF Links

PDF Links PubReader

PubReader ePub Link

ePub Link Full text via DOI

Full text via DOI Download Citation

Download Citation Print

Print