Introduction

Literature Review

1. Brief history and characteristics of OSS

- Flexibility: The OSS emphasizes modification. This feature enables the developer to customize codes for certain problems without having to use the code in any specific manner.

- Reliability and transparency: Most OSS communities are active, and their codes can be fixed and enhanced by various supporters, unlike proprietary software maintained by a single developer or company. In addition, OSS allows developers to verify and monitor the codes without relying on vendors.

- Free of charge: Although OSS incurs a TCO, open-source licensed software is typically offered free of charge. As such, using OSS can reduce the development cost.

- Stability: A professional developer collaboration network maintains the most widely used OSS.

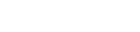

2. OSS for the manufacturing sector

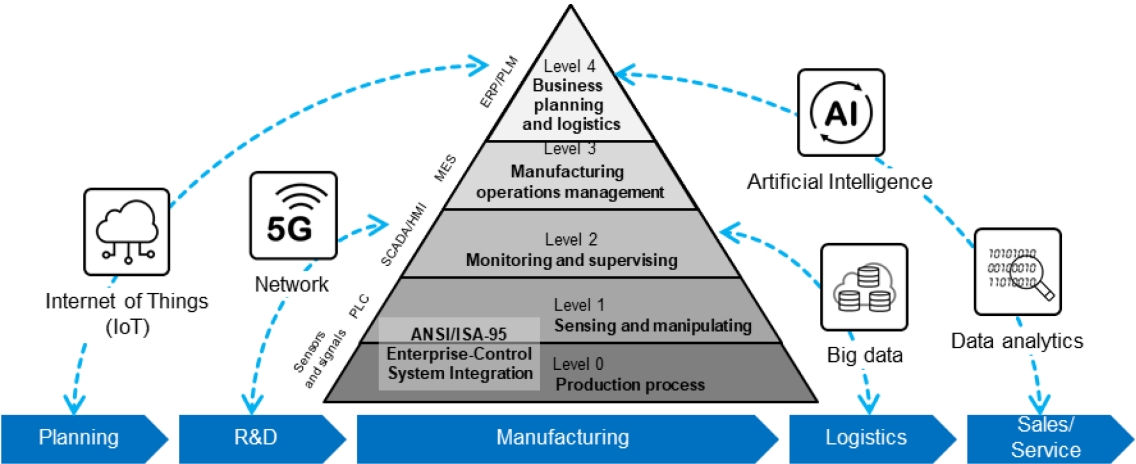

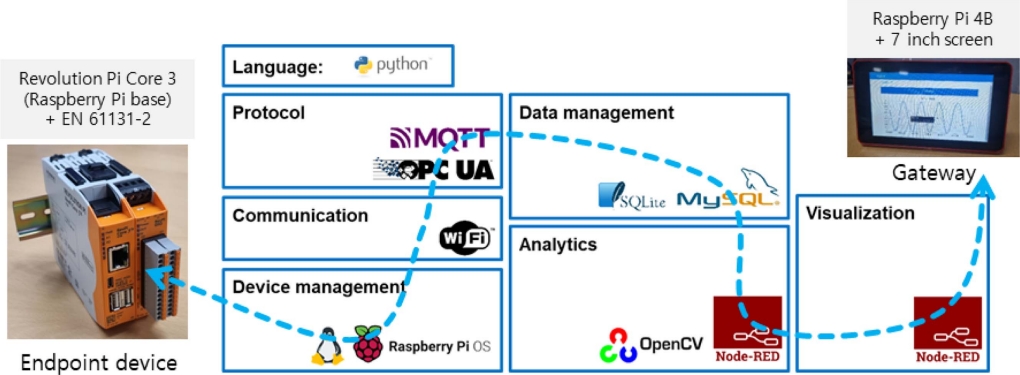

Enabling OSS for Appropriate Smart Manufacturing

1. Requirement analysis

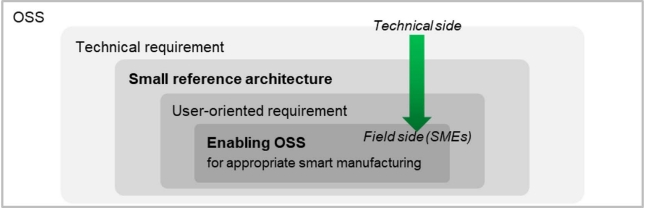

1.1 Technical requirements

- Open-source RAs: FAR-EDGE (Isaja et al., 2017), Edge Computing RA 2.0 (Edge Computing Consortium, 2017), and Industrial Internet Consortium RA (IIRA) (Industrial Internet Consortium, 2017)

- Commercial RAs: Amazon Web Services (AWS) (Amazon Web Services, 2022), Google Cloud (Google Cloud, 2016), and Microsoft (Microsoft, 2022)

1.2 User-oriented requirements

2. Enabling OSS for the proposed small RA

2.1 Candidate for enabling OSS from a literature survey

2.2 Recommendation for enabling OSS for SMEs

3. Evaluation

4. Application scenarios

- Shopfloor environment monitoring: Owing to advances in materials and sensor technologies, various inexpensive and simple environmental sensors are available commercially. Integrating an environment sensor, e.g., a temperature of light sensor, with a single board computer (as edge computing) allows shop floor managers to monitor their workplace status anytime and anywhere (Kwon et al., 2021).

- Computer numerical control equipment monitoring: Recent webcams and smartphones can be used as vision sensors at production sites. Similar to the demonstration performed for the evaluation, images of the human-machine interface of legacy equipment from a webcam or smartphone can be processed in an edge computer using image processing and optical character recognition (OCR) techniques to obtain operational data (Kim et al., 2019).

- Process/product quality monitoring: Similar to the scenario above, the manufacturing process or product can be inspected using a simple vision sensor such as a webcam. For example, defects from fused deposition modeling and sewing stitches were detected in previous studies (Kim, Jung et al., 2022; Kim, Lee et al., 2022; Kim et al., 2020).

PDF Links

PDF Links PubReader

PubReader ePub Link

ePub Link Full text via DOI

Full text via DOI Download Citation

Download Citation Print

Print